Four years of development has already gone into BMW's i sub-brand, and these are the first tangible results: concept versions of two new cars - the i3 electric city car and i8 plug-in hybrid supercar.

Both cars make extensive use of advanced materials, including aluminium alloys and carbon fibre reinforced plastics. BMW sales and marketing director Ian Robertson has been quoted as saying that saving weight using advanced materials is cheaper than adding extra lithium-ion battery capacity.

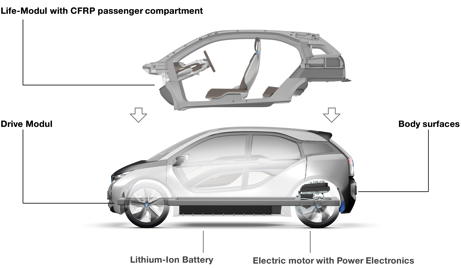

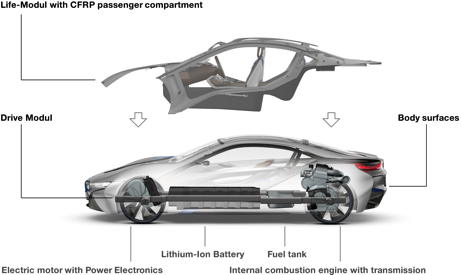

LifeDrive: innovative vehicle architecture

The two new BMWs are based on a new vehicle architecture called LifeDrive, which splits the vehicle into two modules. The Life module is a carbon composite passenger cell which is made, uniquely, using 10% recycled material. The Drive module is an aluminium chassis which combines structural and crash functions and accommodates the drive systems and batteries. A high proportion of secondary (recycled) aluminium is used in both cars to minimise energy consumption in manufacture..

BMW claims that the weight savings resulting from the new architecture offset the extra weight of the electric drivetrain compared to a comparable conventional drivetrain, which can be up to 200kg. The i3 weighs 1250kg, the i8 1480kg.

Crash performance is also said to be good. The Life module incorporates special deformation elements which are said to be able to absorb a large amount of energy in a small area.

Both cars use 19-inch wheels of relatively narrow width, reducing rolling resistance and aerodynamic drag and minimising intrusion into the cabin space.

BMW i3 Concept: premium pure electric vehicle with optional range extender

Andreas Feist, project leader for the BMW i3, has no doubts about the significance of his project: "It is the world's first premium electric vehicle," he says.

The i3's interpretation of the LifeDrive concept splits the two modules horizontally. The Life module is a four-seat body with a flat floor, opposed "coach" doors and 200 litres of luggage space at the rear. The interior is trimmed with natural fibres from renewable sources. All the drive controls are concentrated on the steering column, eliminating the need for a centre console.

The Drive module is an aluminium perimeter frame with a lithium-ion battery mounted low in the centre for a low centre of gravity, the aluminium side members and crush zones front and rear providing crash protection. The battery has a built-in liquid heating/cooling system which maintains the cells at their optimum temperature of 20degC to improve performance and range, and the battery can be pre-conditioned to the right temperature using a timer.

An electric drive motor, the same permanently excited hybrid synchronous motor already tested in the BMW ActiveE, is mounted over the rear axle. The motor and power electronics were developed in-house by BMW. The system in 40% smaller than the early system in the Mini E.

The motor provides 125kW (170PS) and 250Nm (184lbft) and the i3 Concept will accelerate from 0-60km/h (37mph) in four seconds and 0-100km/h (62mph) in eight seconds. It has a top speed of 93mph.

BMW says the battery can be fully charged from a standard electricity socket in six hours, and an 80% charge from a rapid charger takes just one hour. An optional range extender, a super-low emission (SULEV) petrol engine, can be mounted over the rear axle next to the drive motor.

In town 75% of "braking" will actually be achieved using the braking effect of the electric motor acting as a generator. The accelerator pedal also has a distinct neutral position where the i3 coasts without using energy from the battery. The i3 has an ECO PRO mode which alters the accelerator pedal response to limit power output, and operates the climate control system in a minimum-energy mode. An ECO PRO + mode applies even more extreme limits on energy usage to maximise range.

The i3 incorporates Proactive Front Protection, a form of predictive emergency braking, an automated parking system and a traffic jam assistant which helps steer the car at low speed.

BMW i8 Concept: plug-in hybrid performance car

The BMW i8 Concept uses a modified version of the electric drive system from the i3 to power the front wheels, with the traction battery mounted in what BMW calls an "energy tunnel" in the centre of the car. That leaves space for a turbocharged three-cylinder internal combustion engine to drive the rear wheels. The arrangement of the two drive units gives 50/50 weight distribution.

The engine develops 164kW (220PS) and 300Nm (221lbft), and can work in conjunction with the 96kW electric motor to accelerate the i8 from rest to 100km/h (62mph) in less than five seconds. The i8 has a governed top speed of 155mph.

BMW says the i8 will return 40-56mpg in normal use, with the potential for up to 93mpg. The i8 will travel up to 20 miles on electric power. On the move, the lithium ion battery is recharged using regenerative braking, which benefits from the front axle position of the electric drive system where the greatest brake forces are required. The battery can also be recharged using a high-voltage alternator on the engine.

The i8's aerodynamics are claimed to be "extremely efficient in terms of lift and downforce at both axles". Intake air for the engine is taken in at the rear of the passenger cabin, and turning vanes at the rear manage the airflow over the rear window to reduce drag.

Braided carbon fibre for light weight and high strength

In addition to extensive use of components made from resinated carbon fibre cloth, the i8 also uses "braided profiles" - sock-like woven tubes. These provide greater design freedom, allowing easier control of wall thickness, reducing the number of joints required and making it easier to construct more complex shapes.

The result is a structure which is lighter and at the same time cheaper and less energy-intensive to build. The braided profiles are used in the construction of doors, sills and A-pillars.